AI Technologies Services – BIW Design, Simulation & Manufacturing Solutions

Back to Services

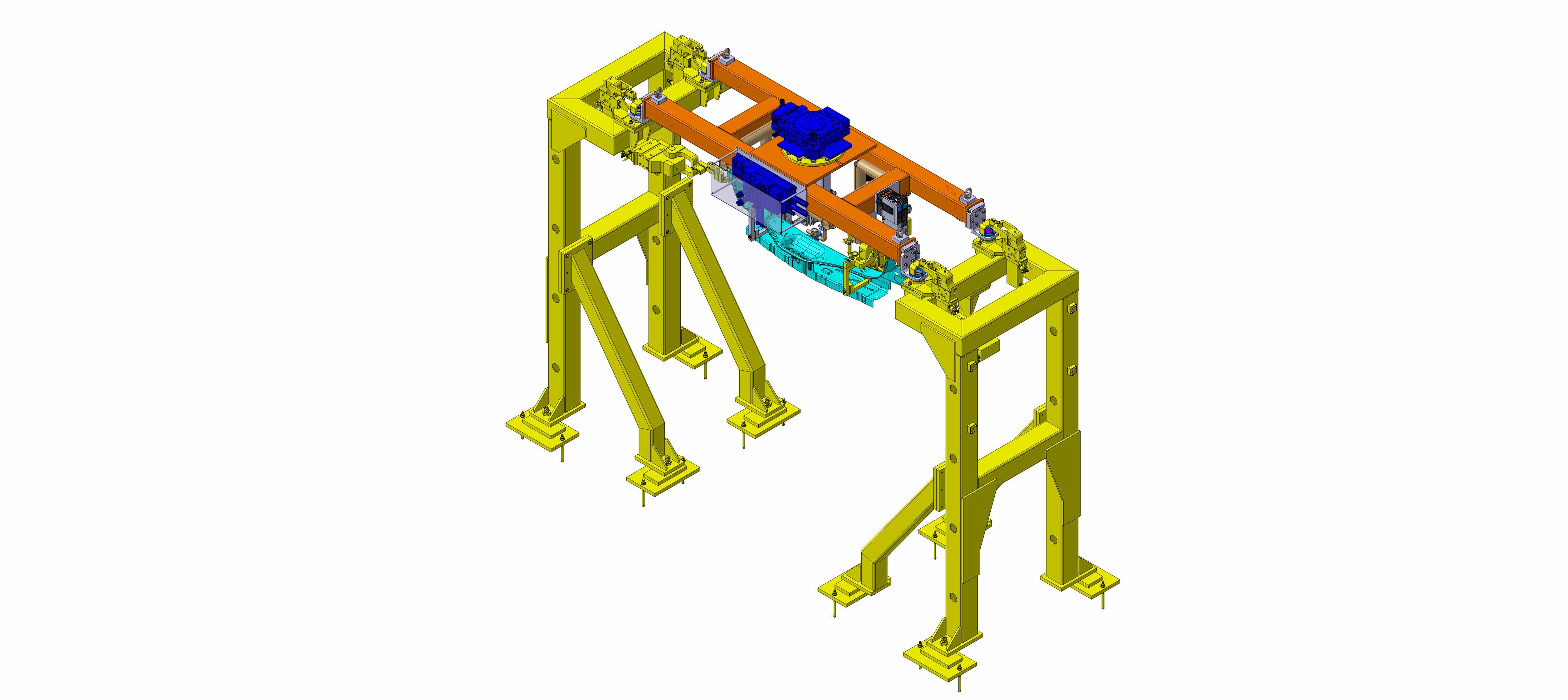

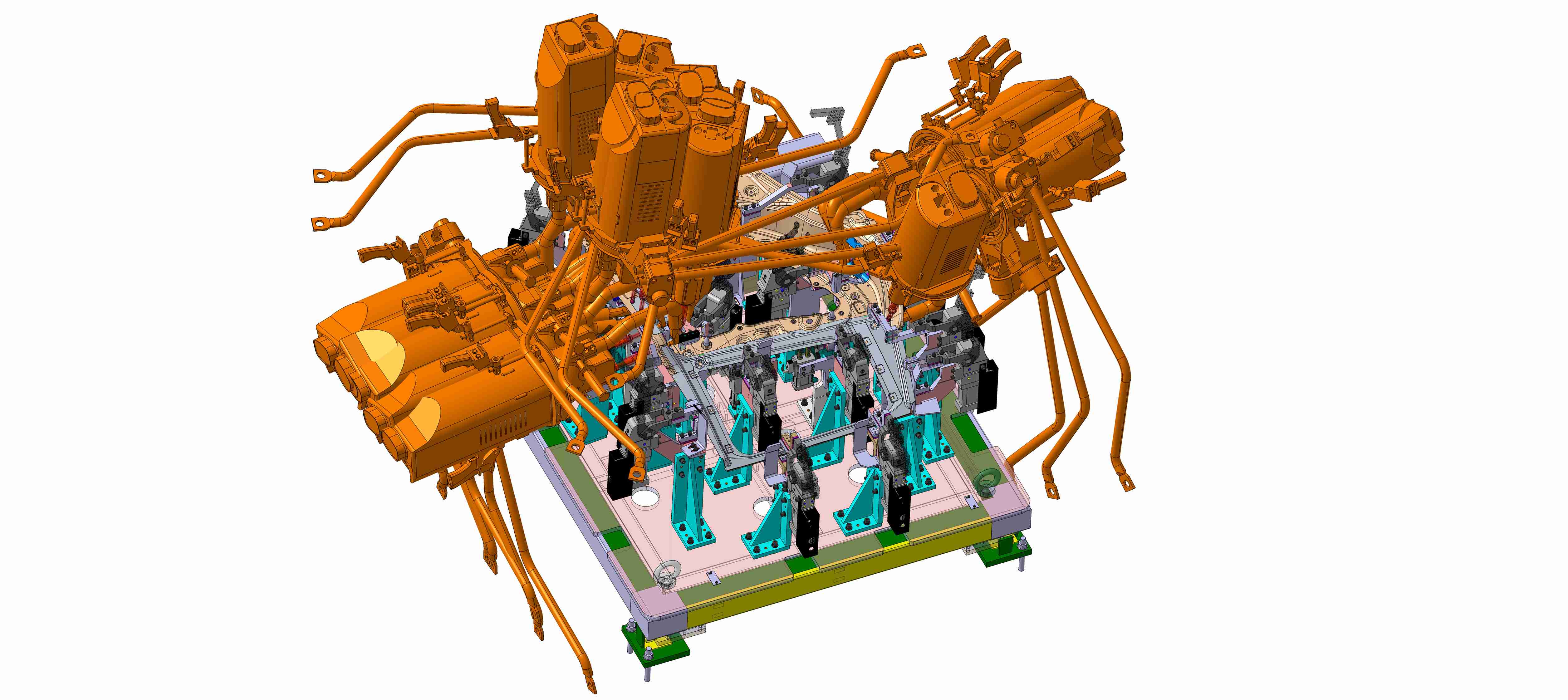

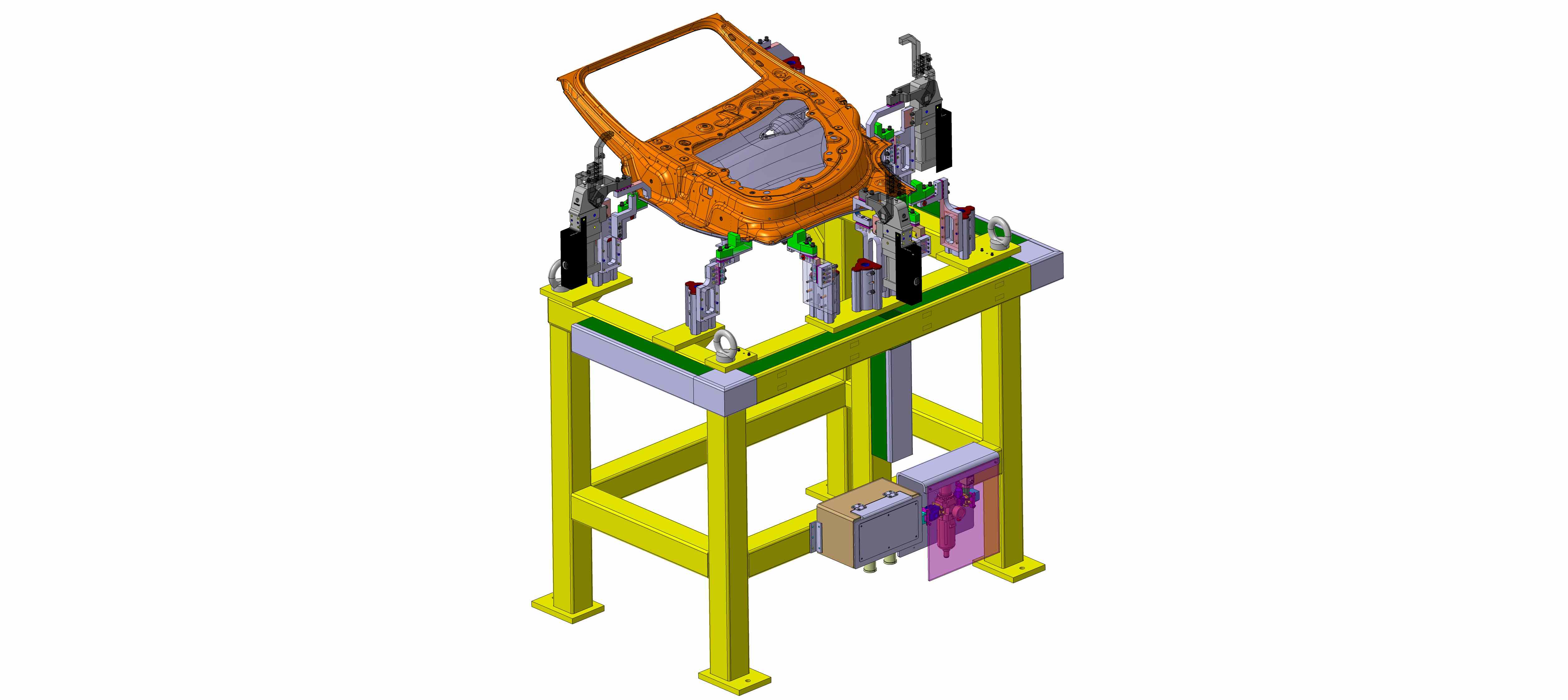

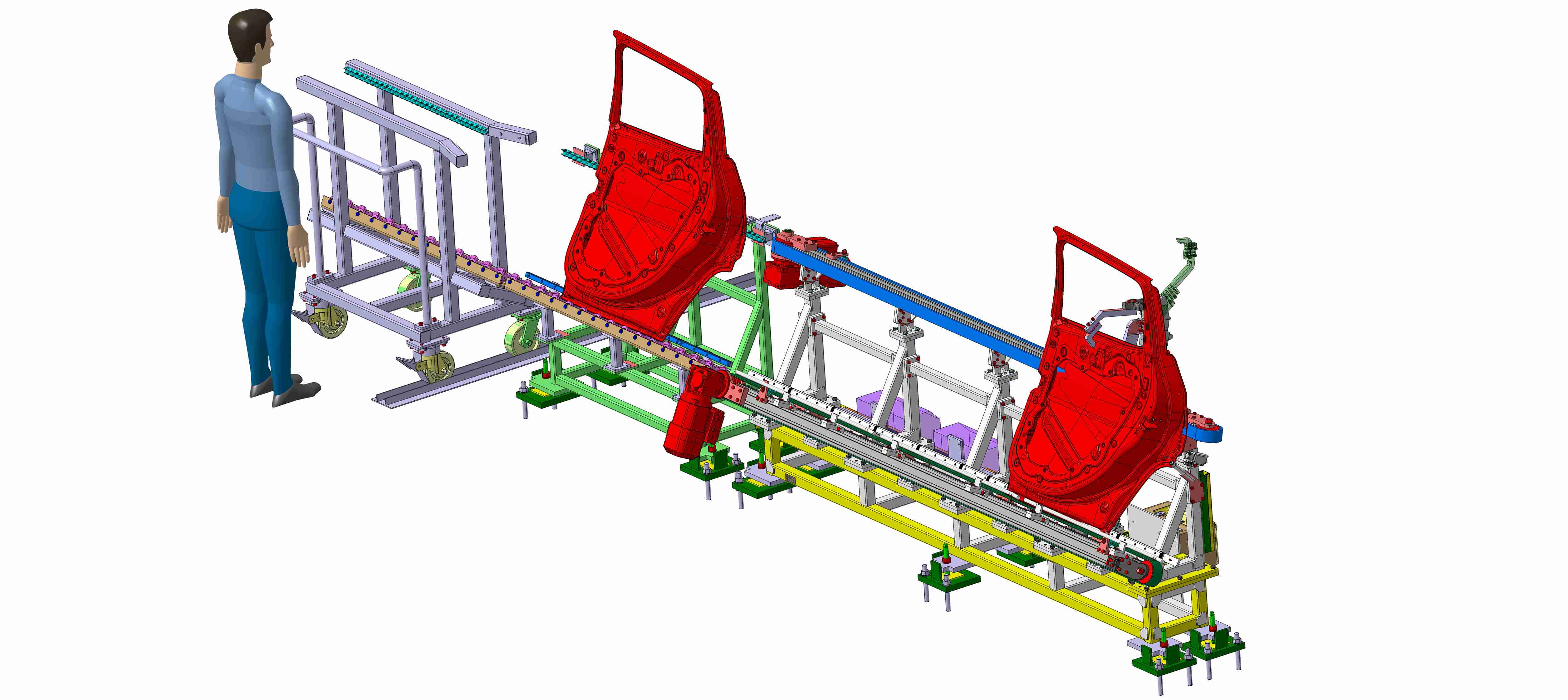

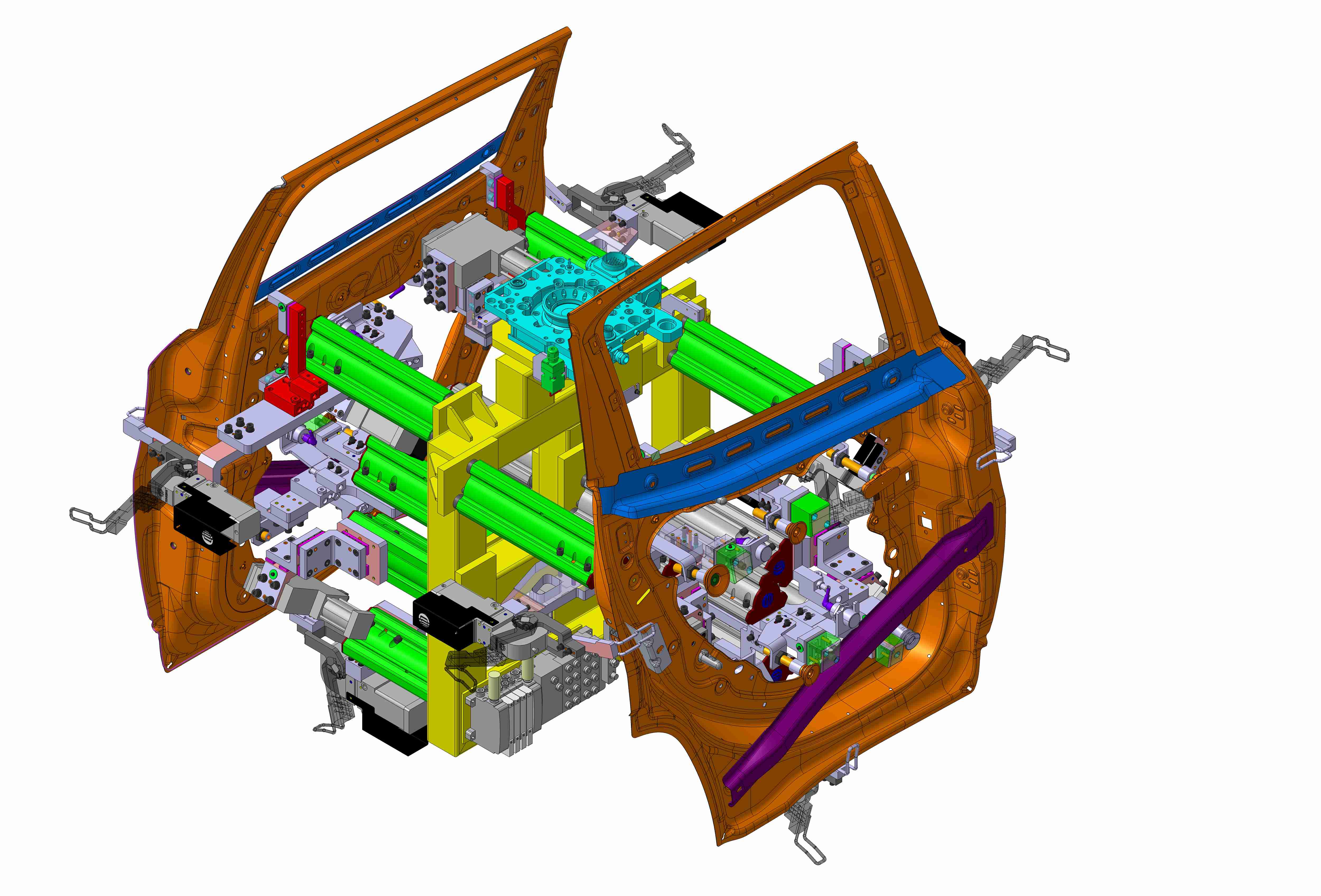

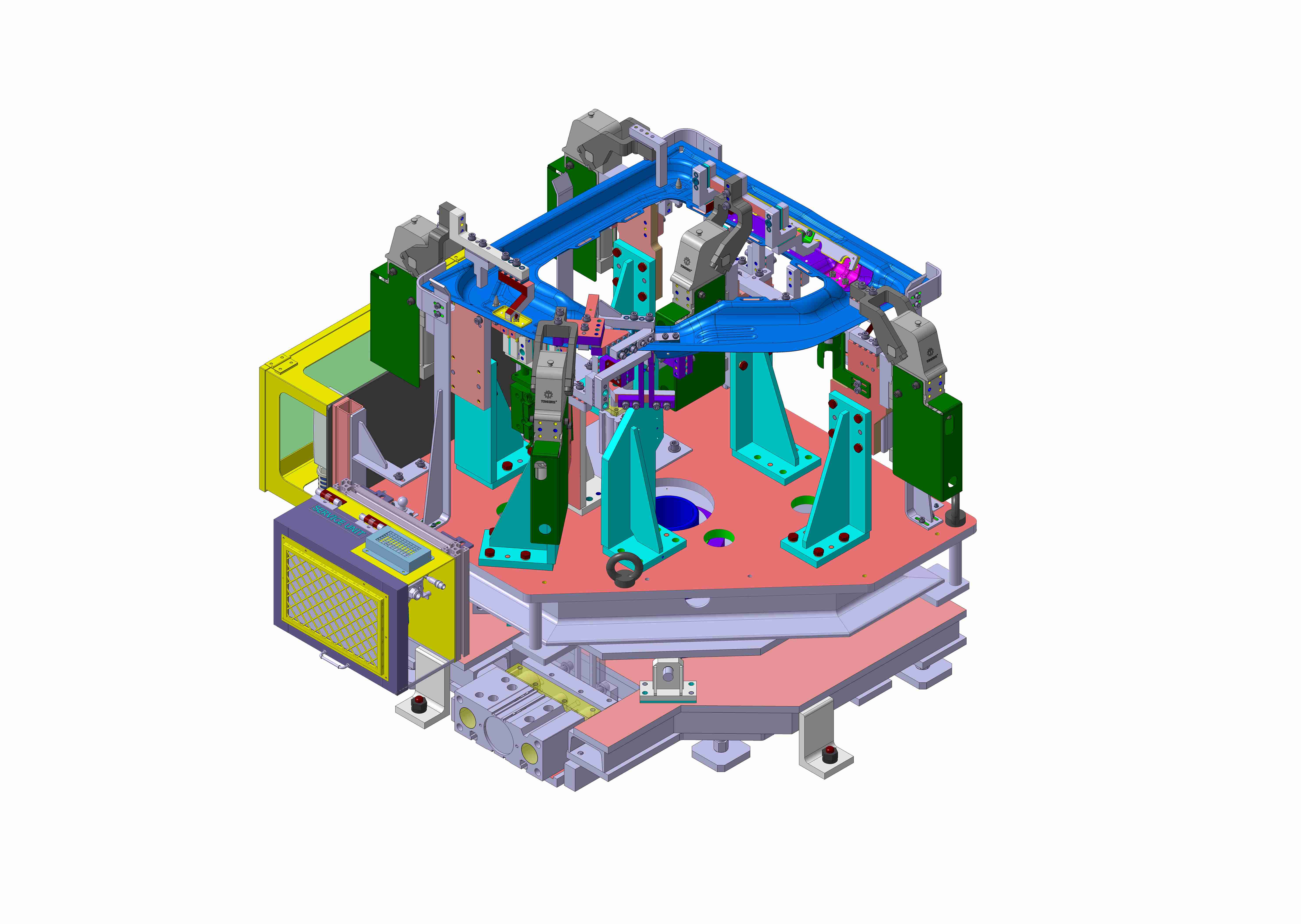

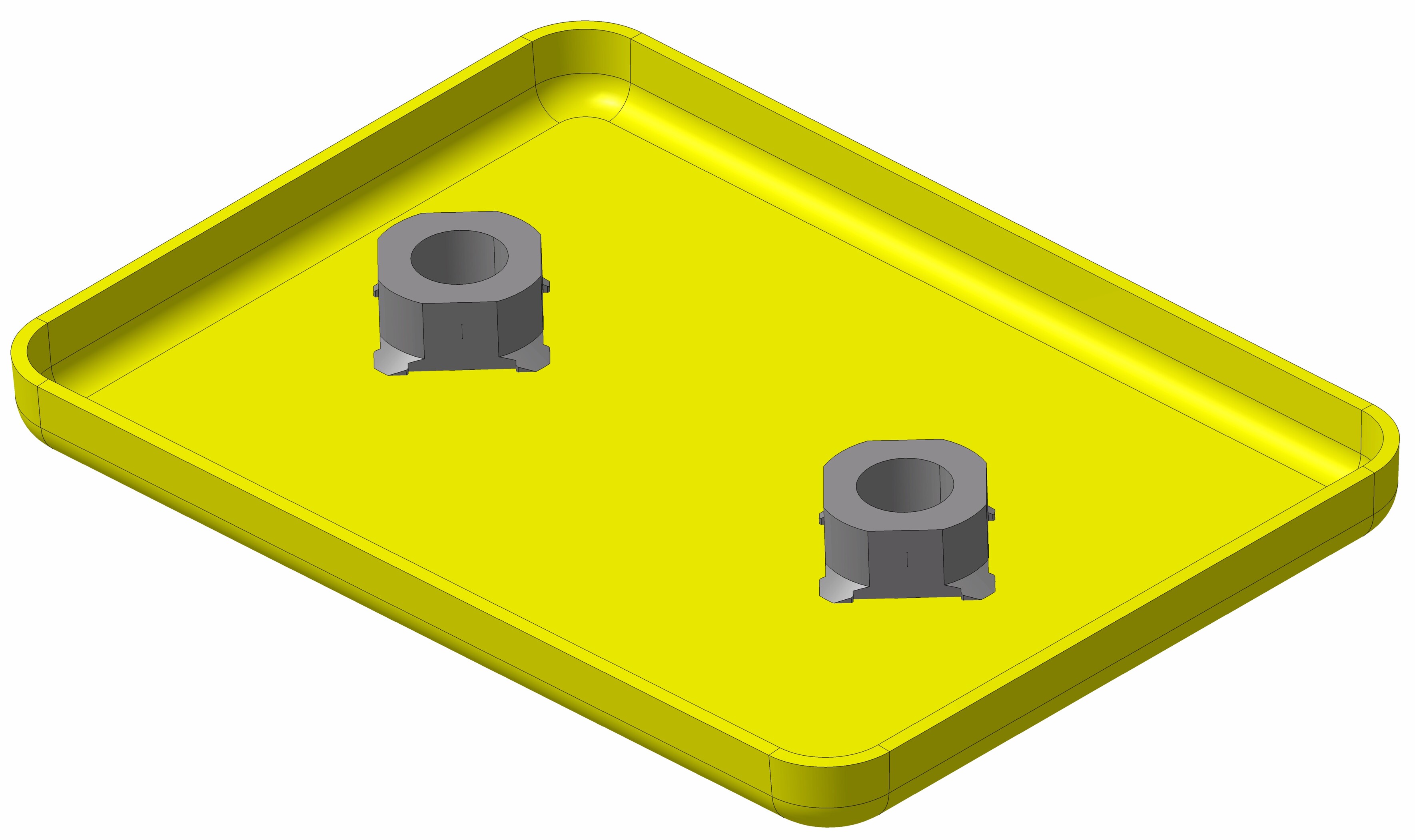

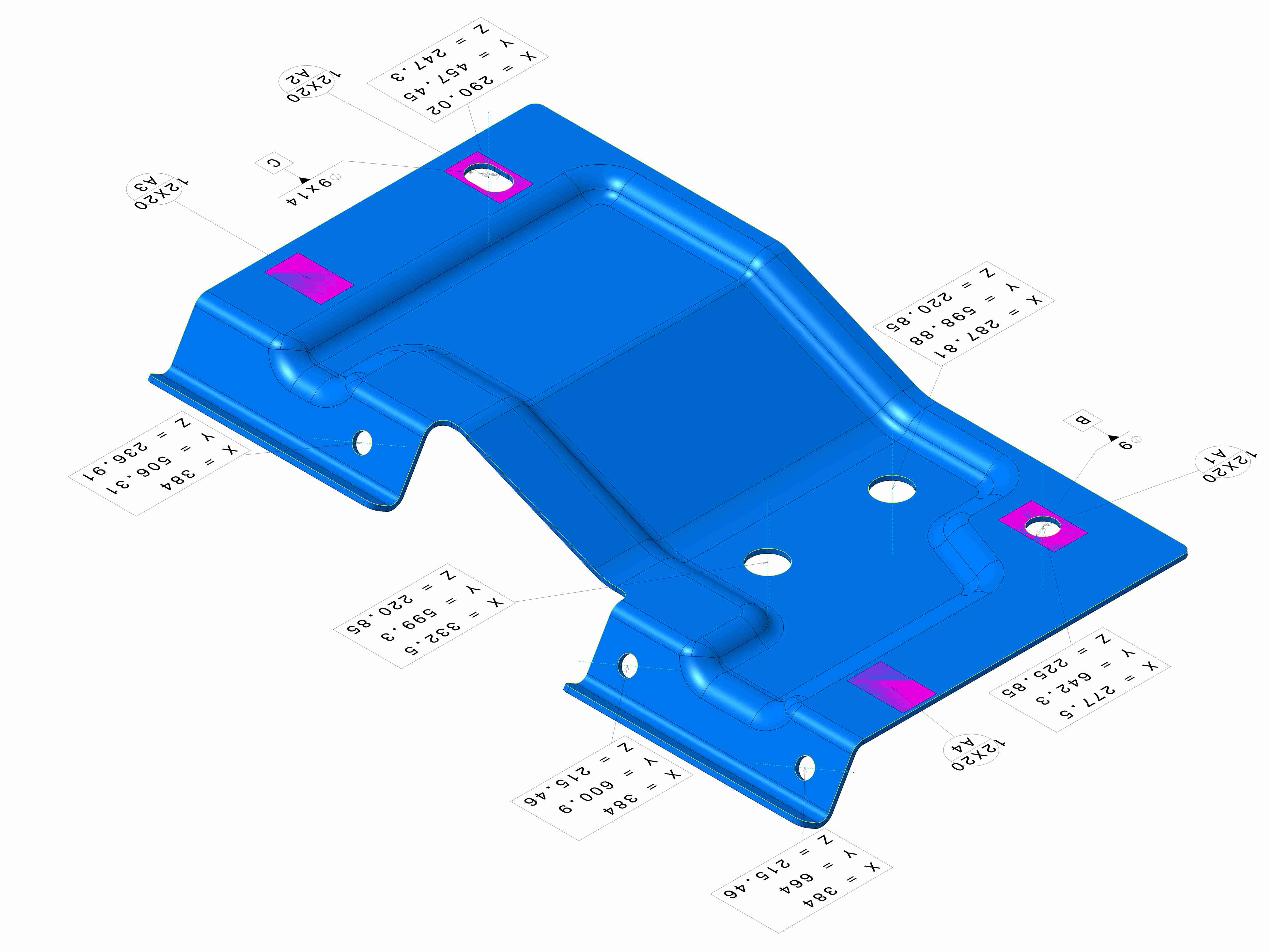

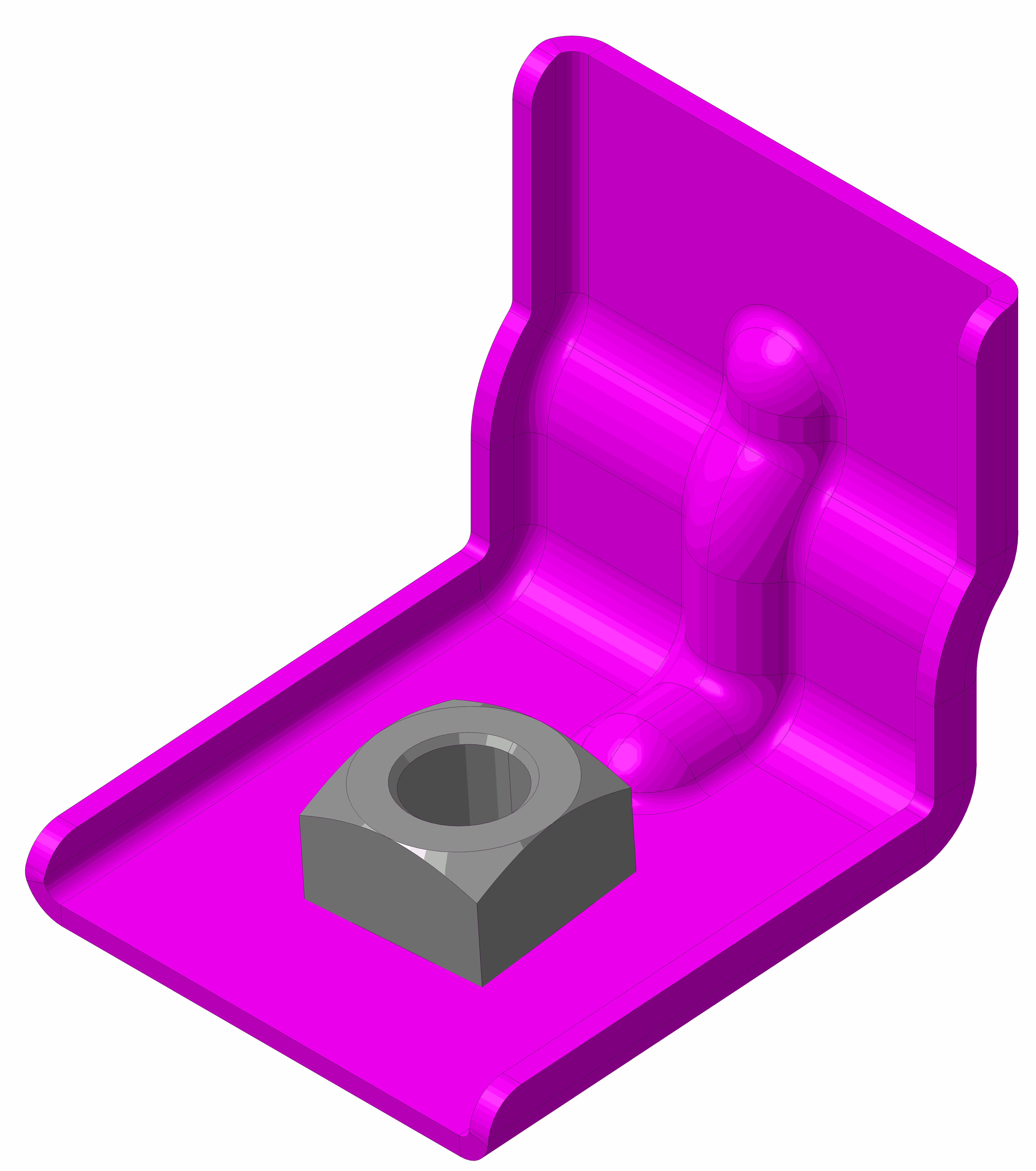

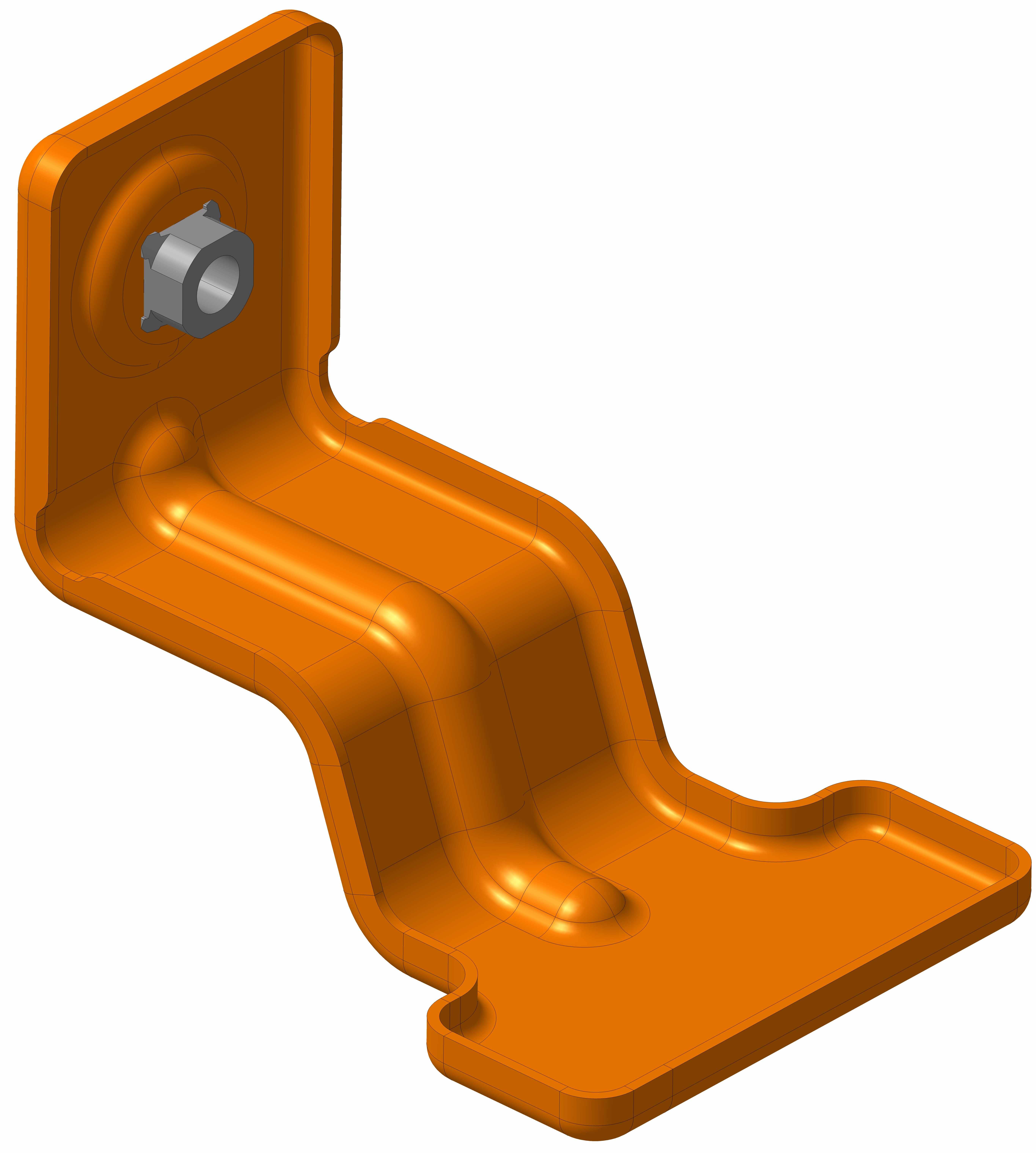

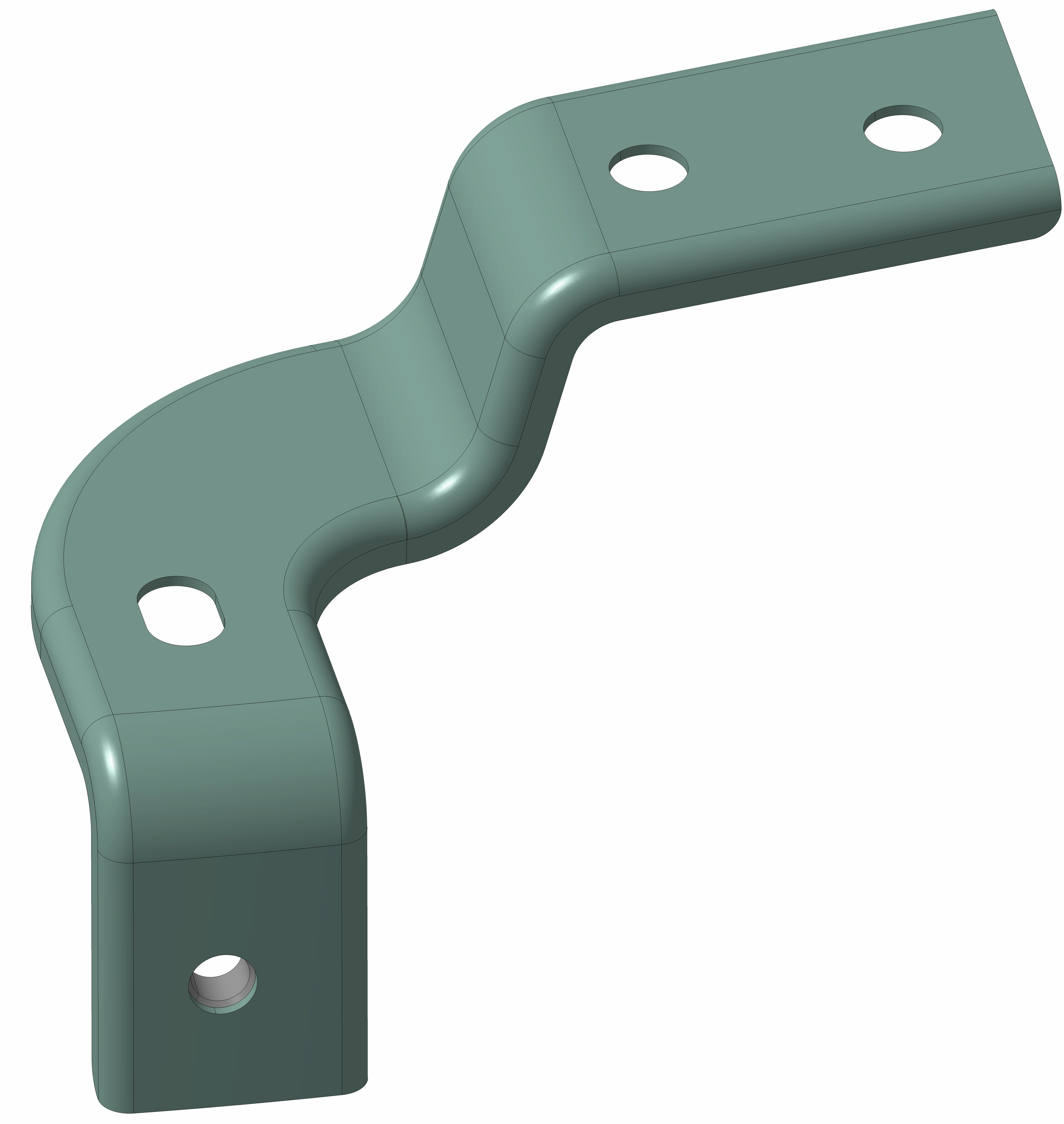

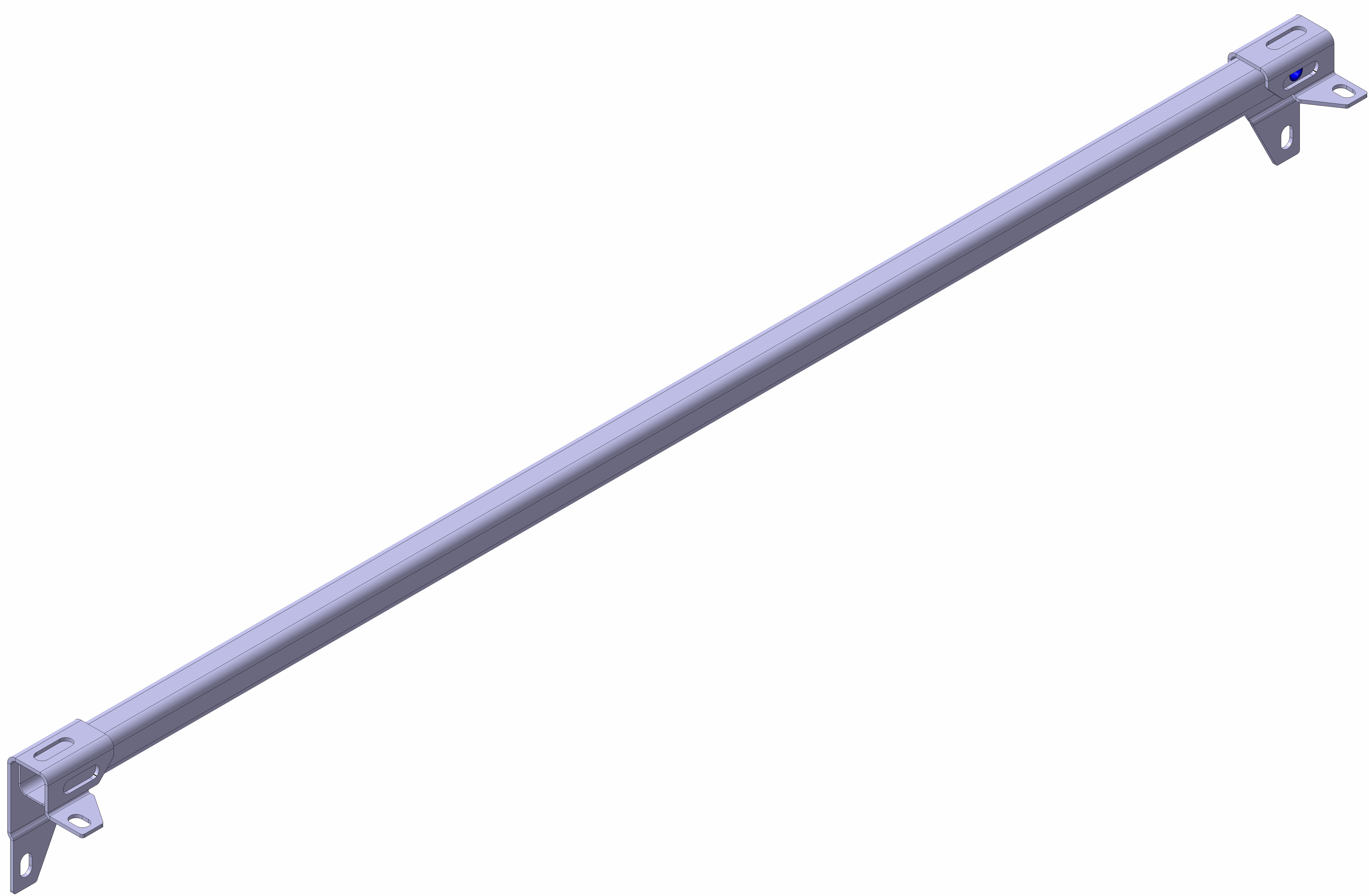

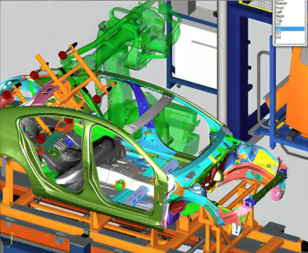

BIW Fixture Design

BIW fixtures play a critical role in the automotive manufacturing process by ensuring that the body components of a vehicle are accurately positioned and held in place during assembly. Our BIW fixture designs provide robust solutions that are essential for the assembly line, enhancing the overall production efficiency and maintaining high precision during the manufacturing process.

Key Features

- High precision fixture designs using advanced CAD/CAM software.

- Optimized production efficiency to minimize downtime.

- Compliance with automotive standards for quality and safety.

We design adaptable fixtures for various body styles, ensuring high precision and ease of setup.

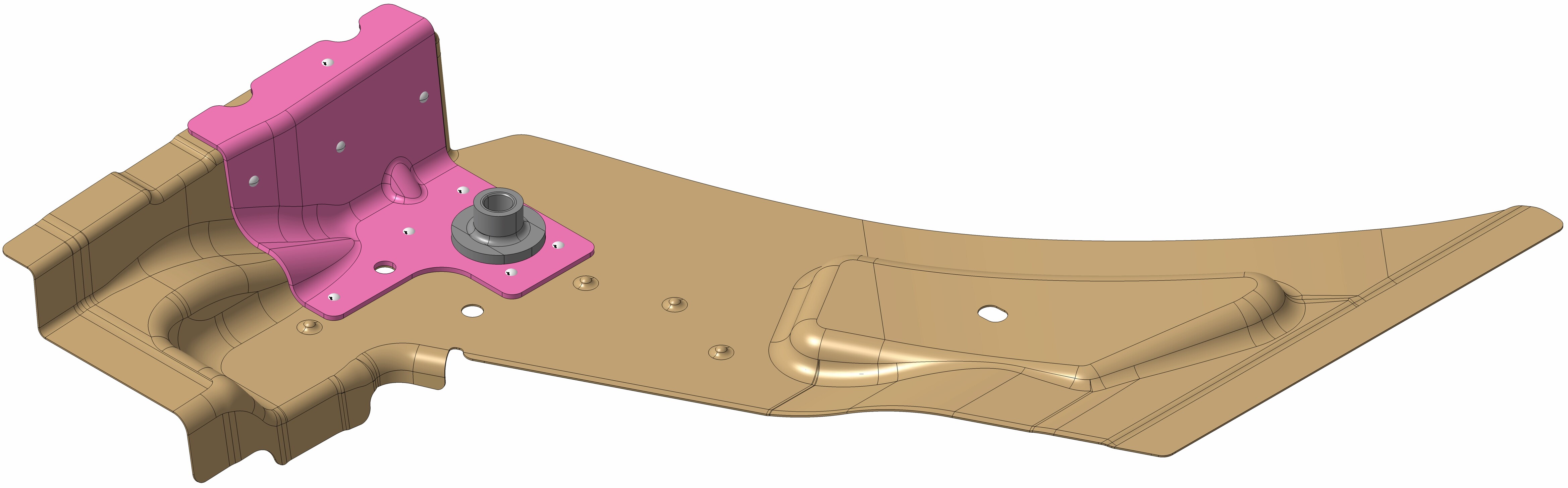

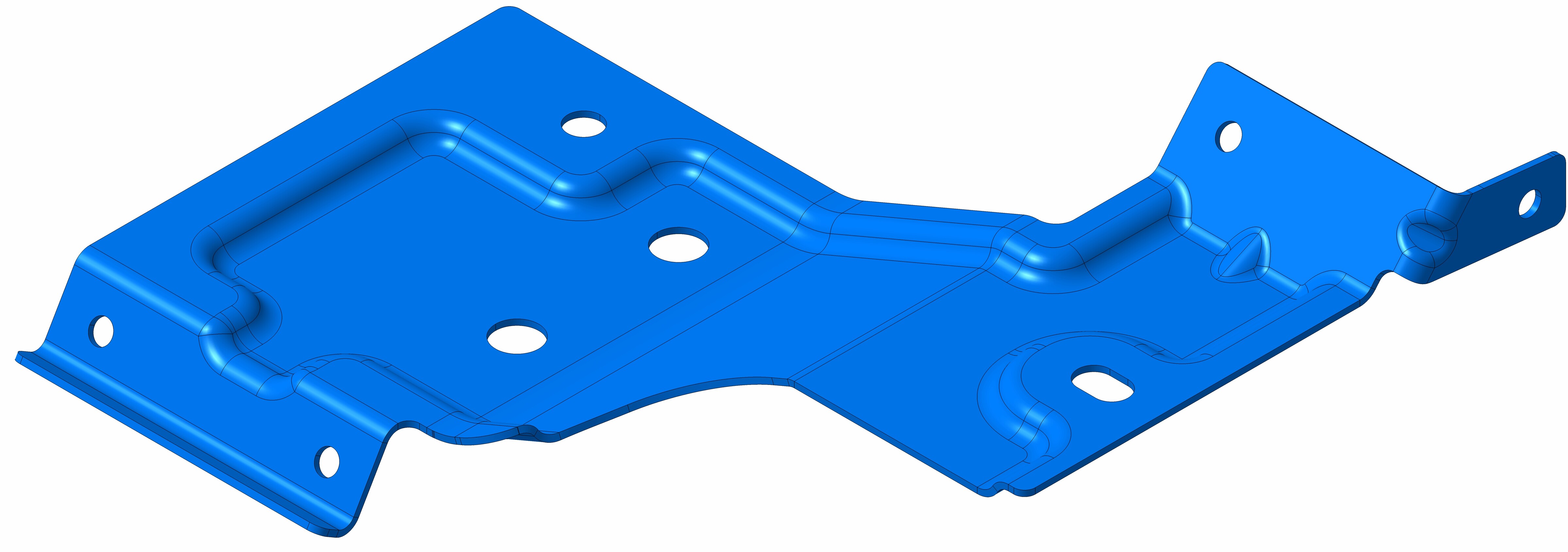

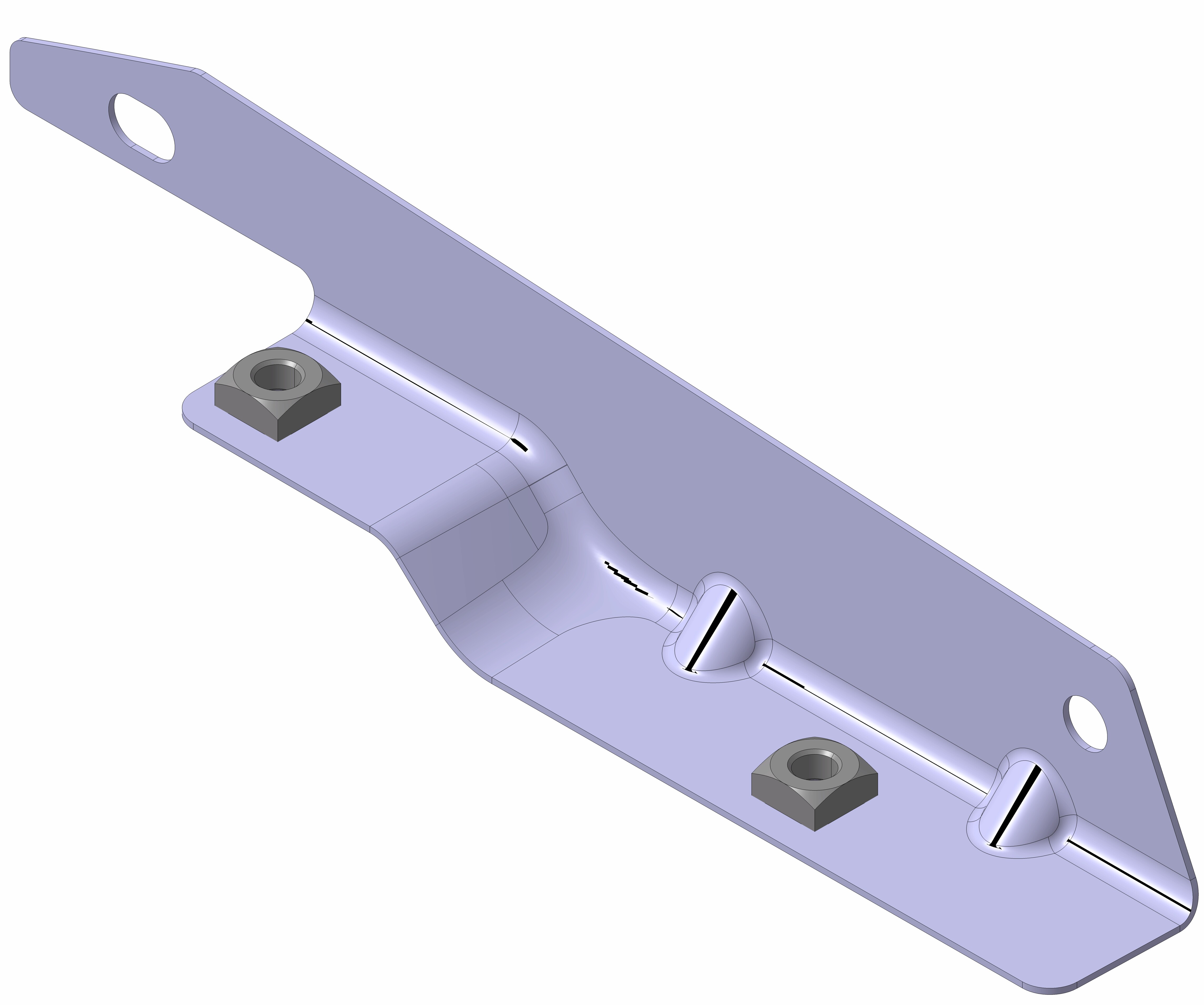

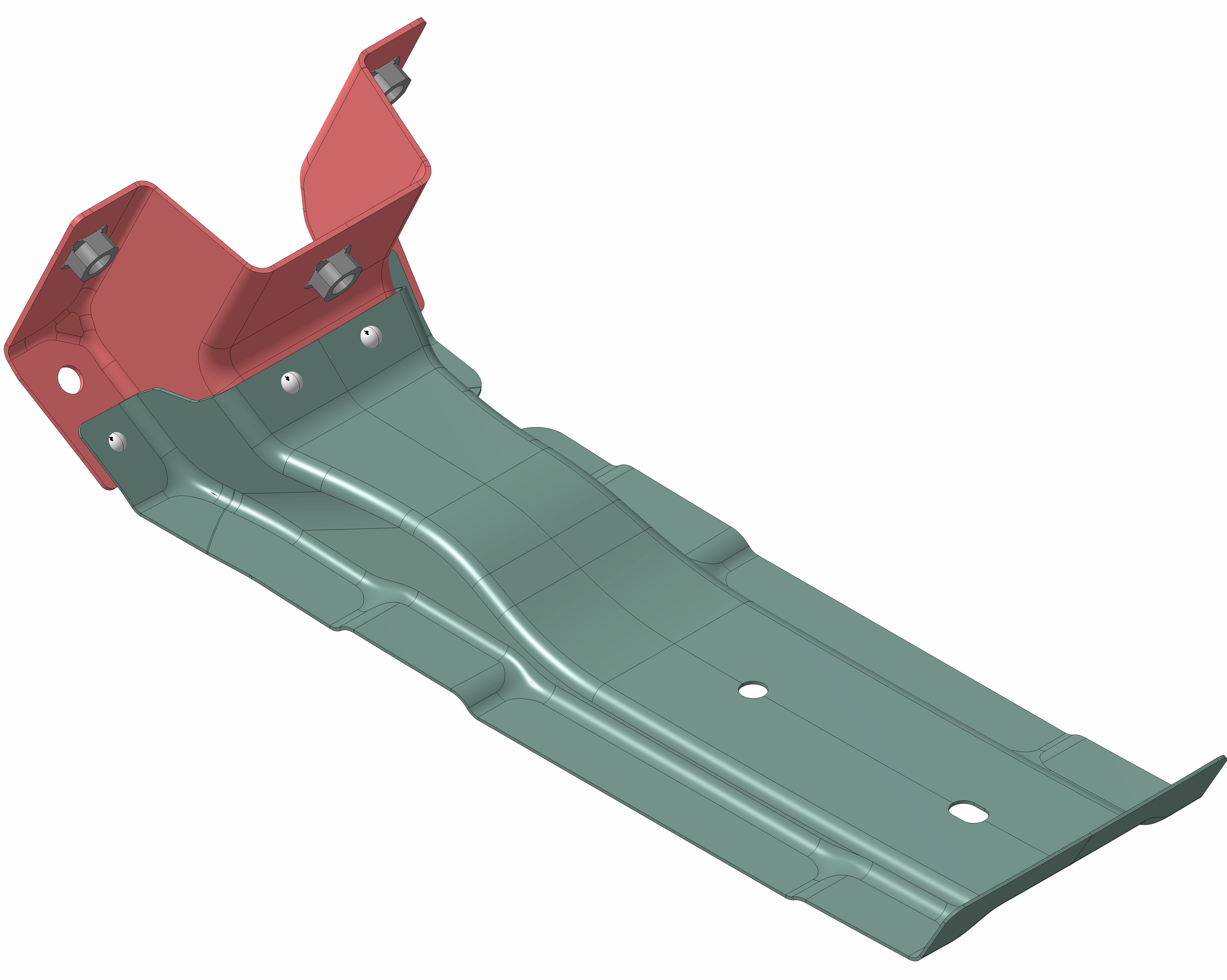

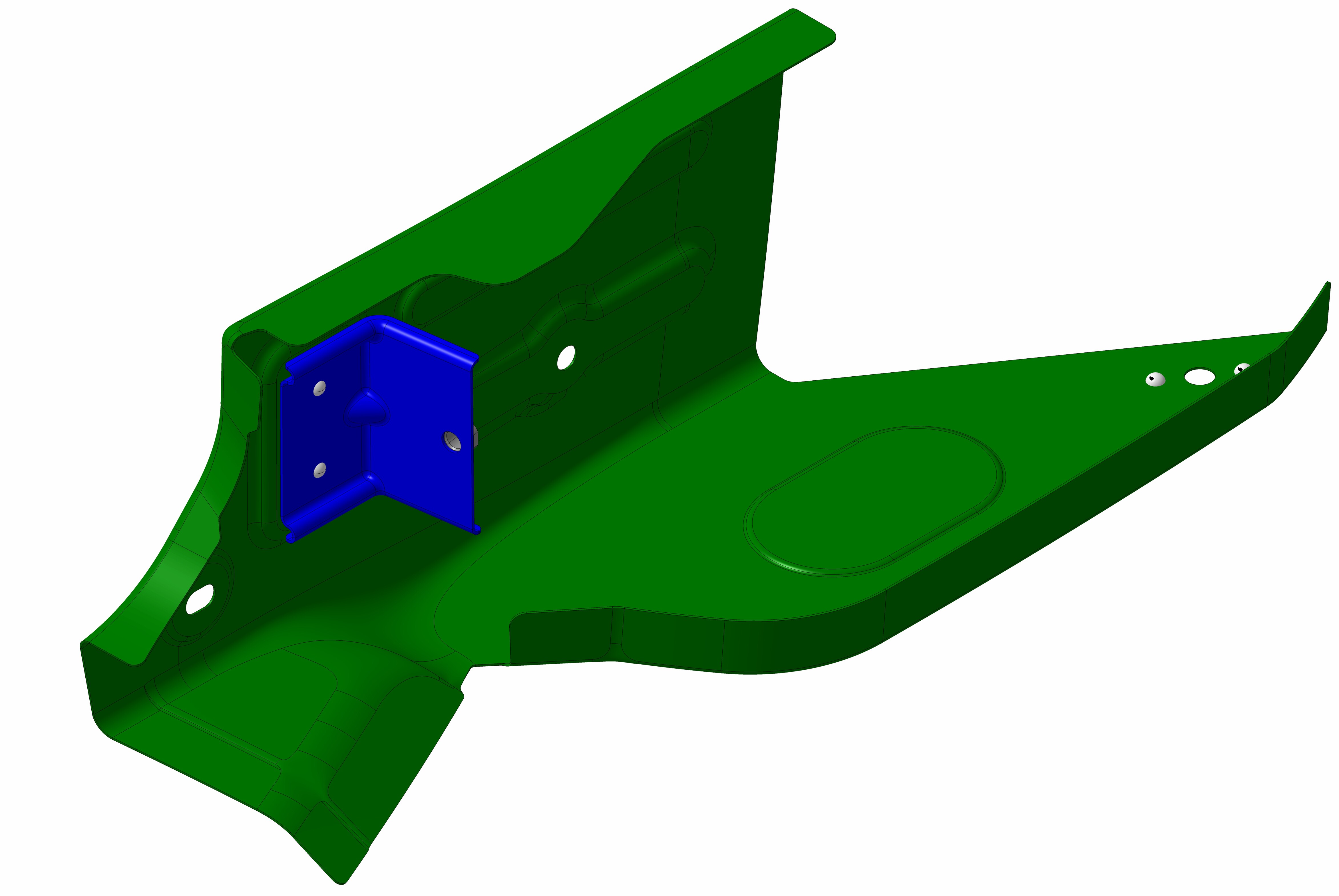

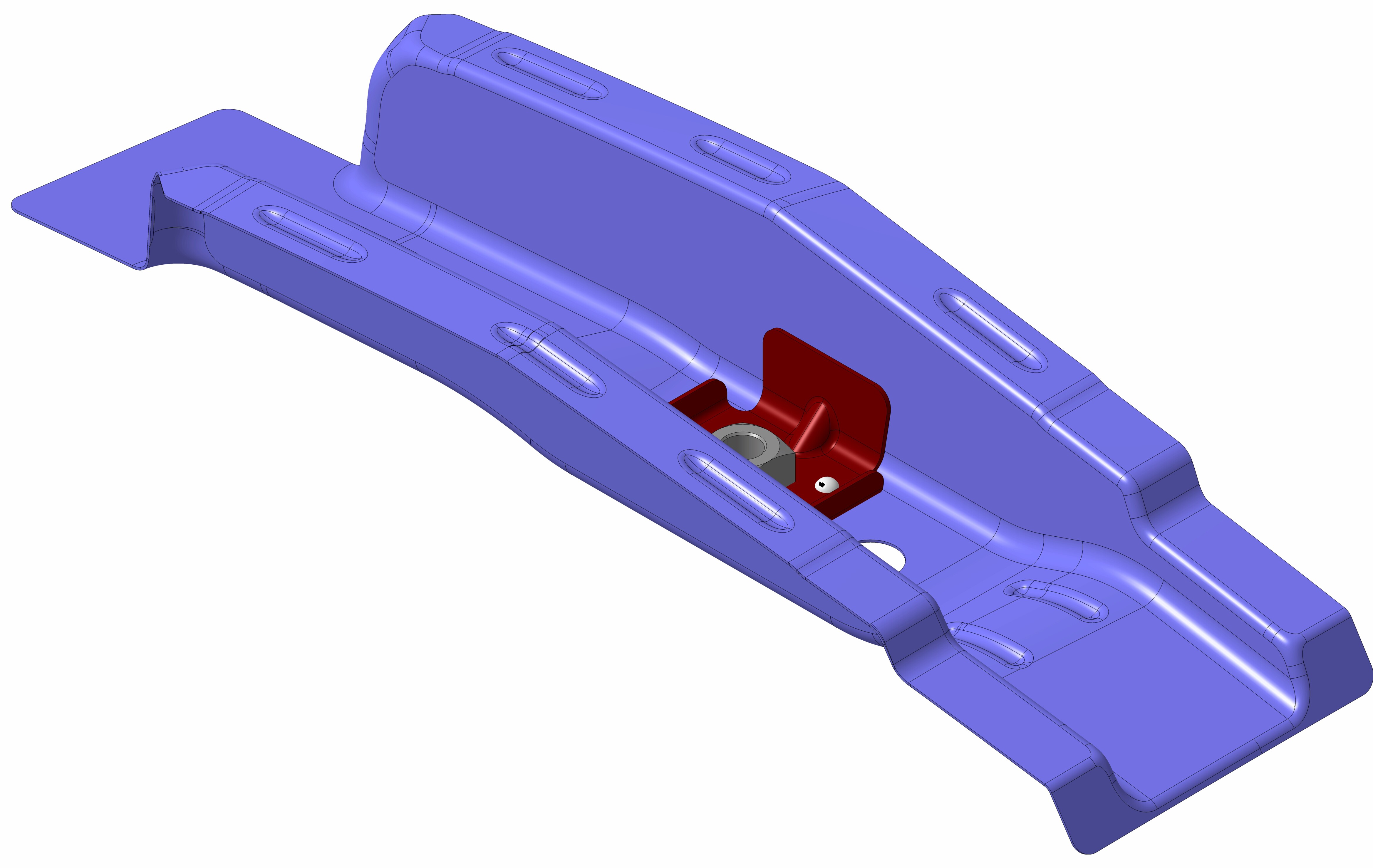

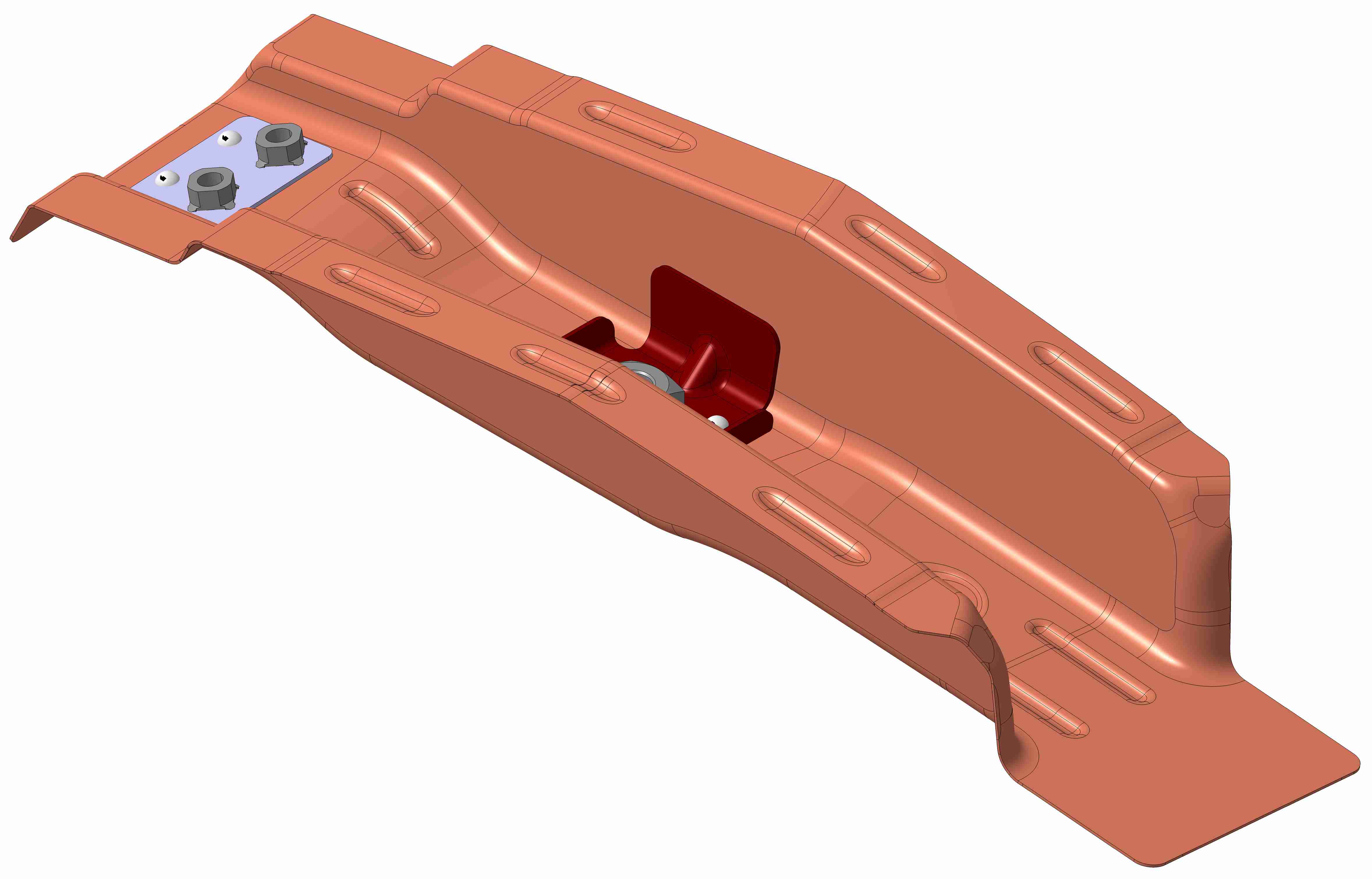

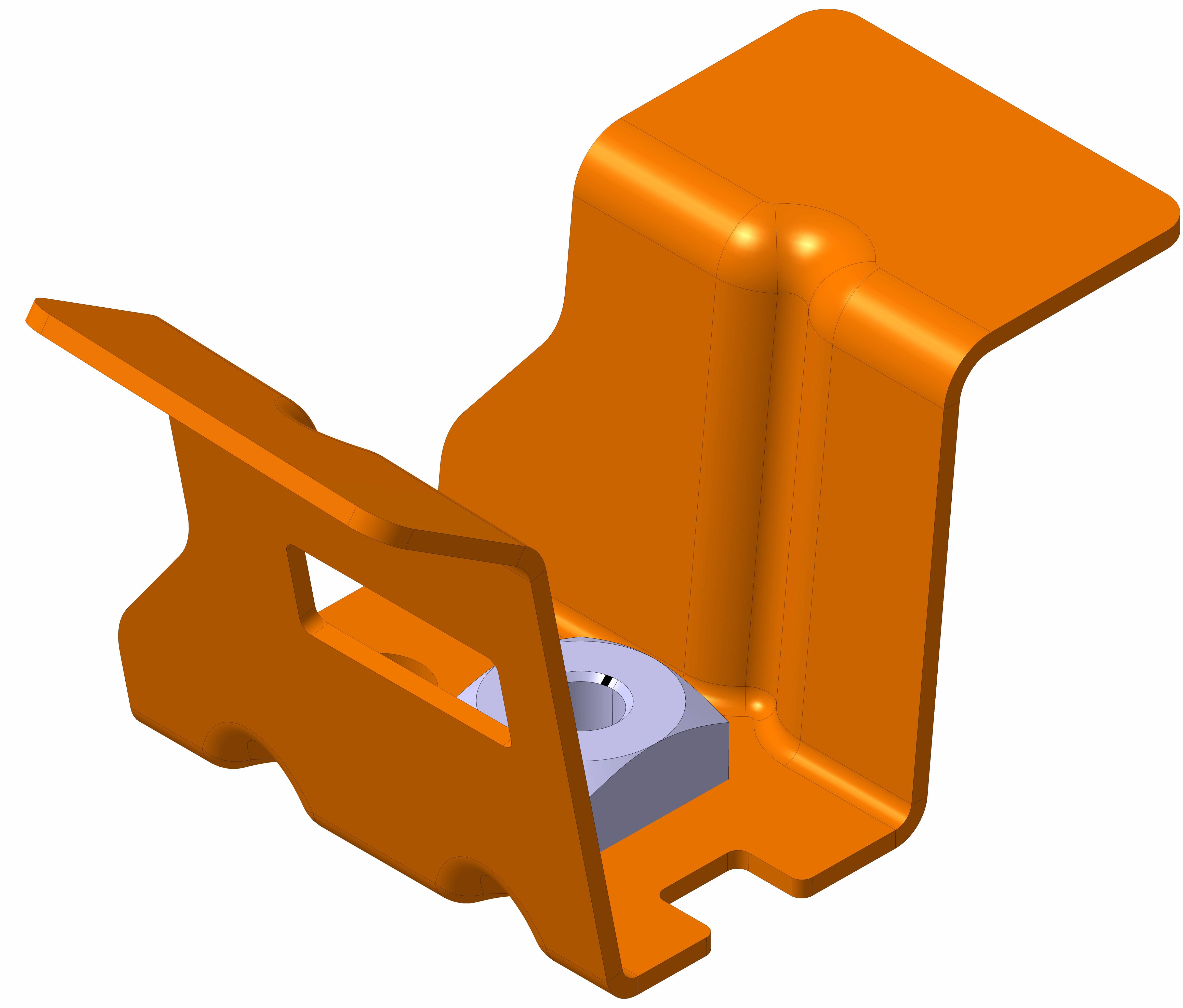

BIW Product Design

BIW product design is essential for developing lightweight, durable, and structurally sound vehicle bodies that meet stringent automotive safety standards. We offer a comprehensive design service that covers the entire lifecycle from initial conceptualization to production, ensuring that the final product is optimized for manufacturing and real-world performance.

Key Features

- Conceptual design and feasibility analysis with advanced simulation tools.

- Material optimization using high-strength steel and aluminum alloys.

- Compliance with industry regulations for safety and crashworthiness.

We integrate simulations to optimize design before prototyping, ensuring cost-effective solutions and safety standards.

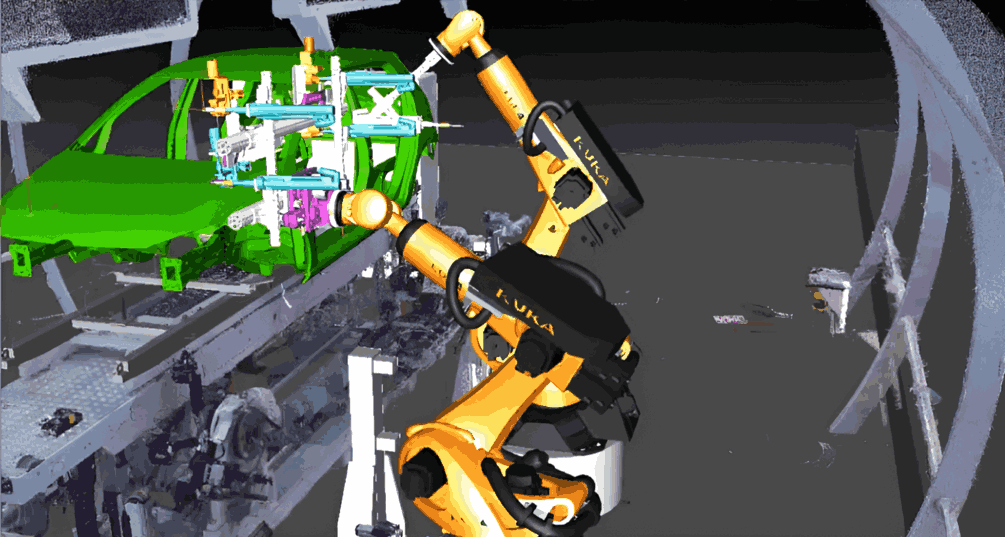

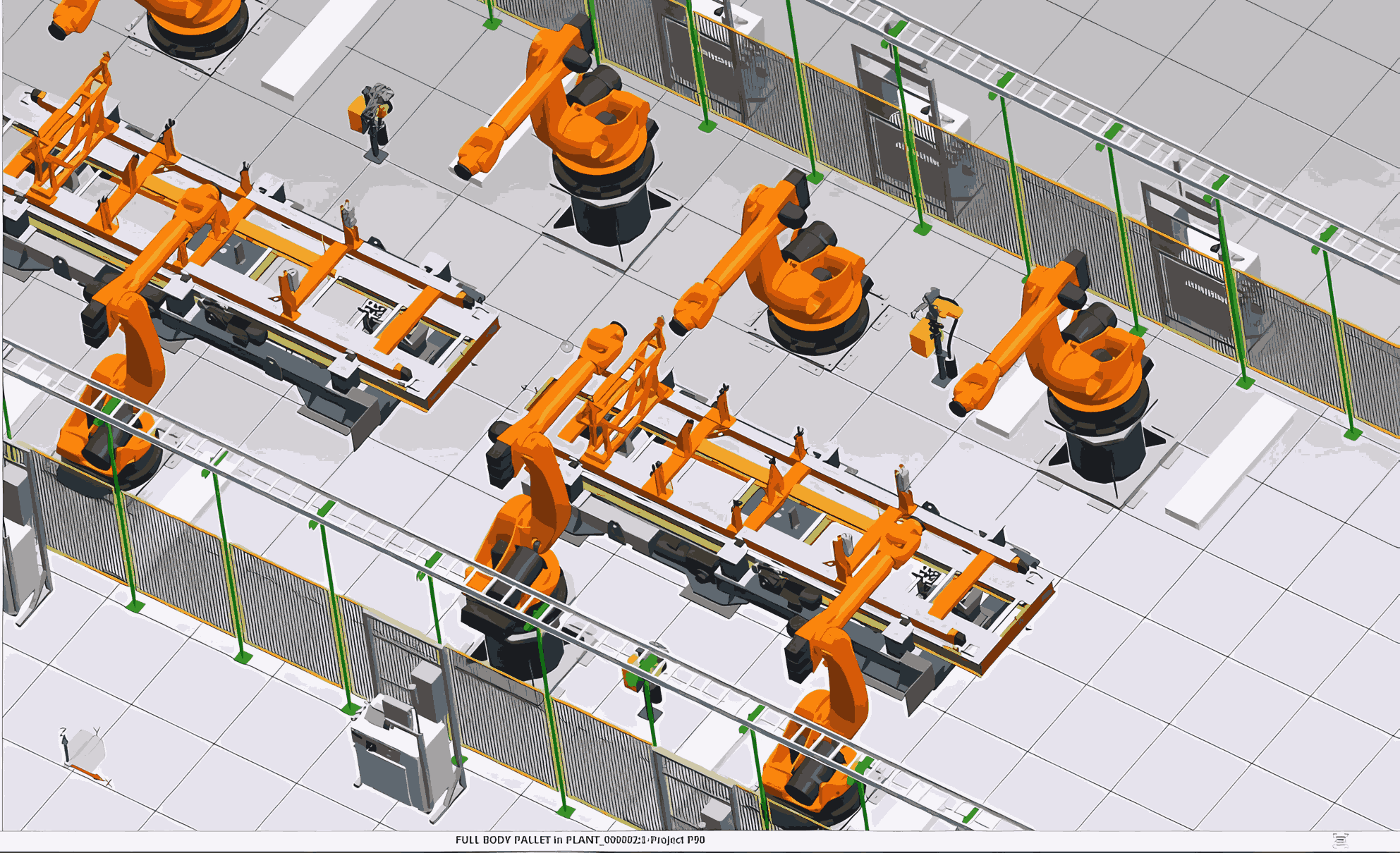

Simulation

Simulation is at the core of modern manufacturing, enabling businesses to test processes virtually before physical implementation. By using tools like Process Simulate and Dalmia, we help our clients achieve optimal manufacturing processes, robotic programming, and ergonomics analysis, saving time and reducing costly mistakes.

Services Include:

- Process validation and optimization for improved throughput.

- Robotic programming simulation to ensure proper movement and function.

- Ergonomic analysis to enhance worker productivity and safety.

Our simulations provide insights into production processes, making it easier to spot inefficiencies and make necessary adjustments.

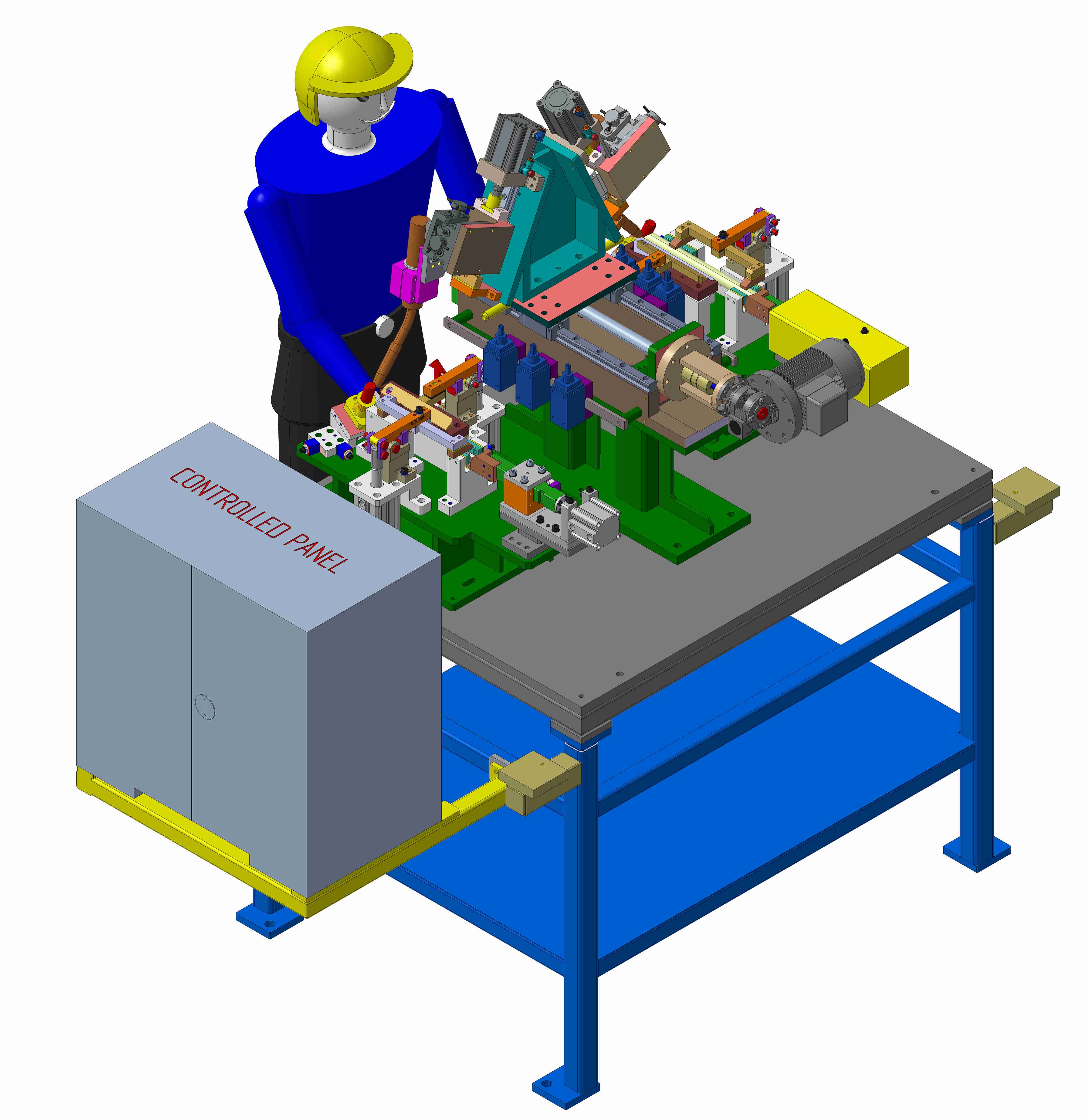

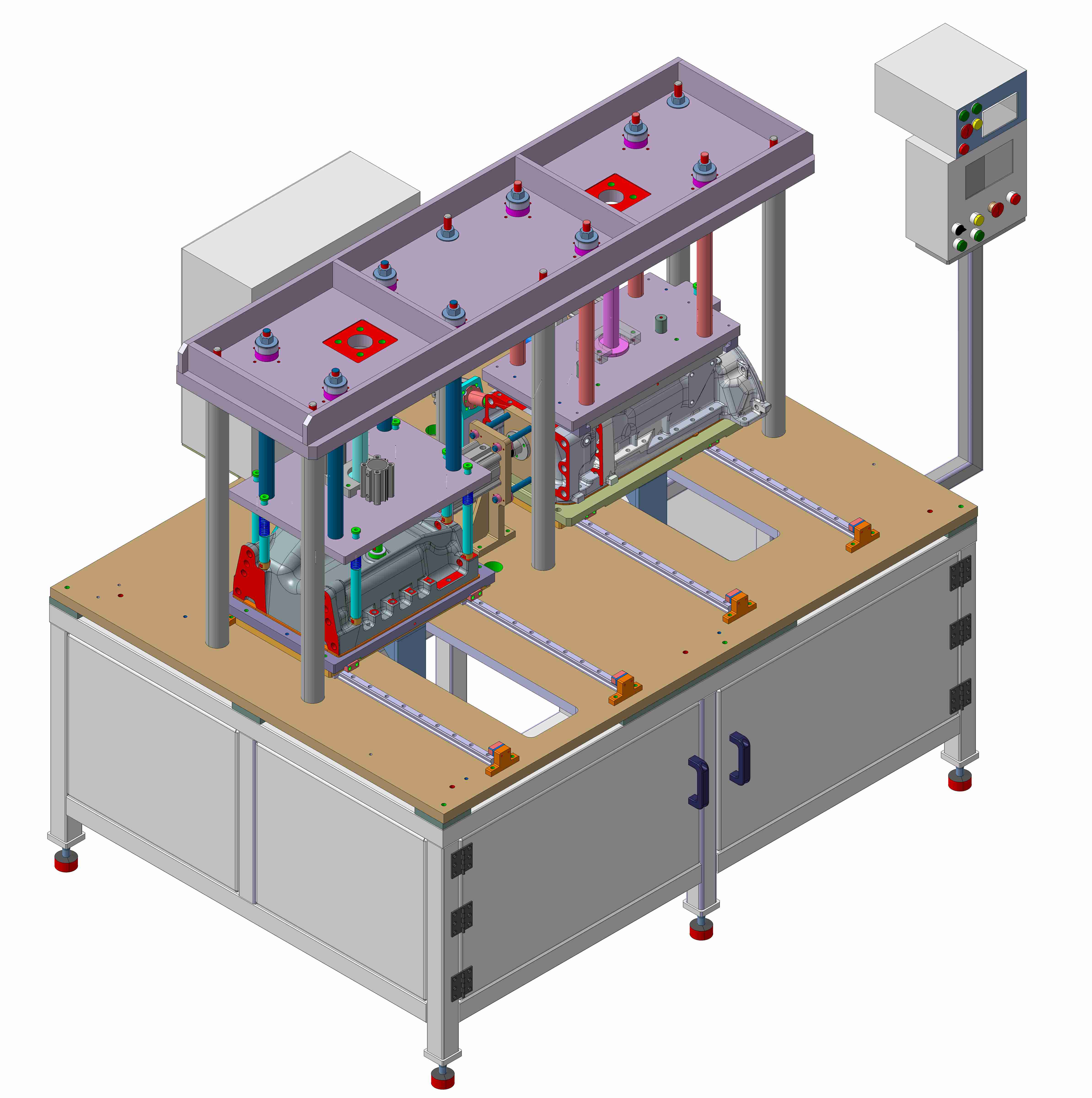

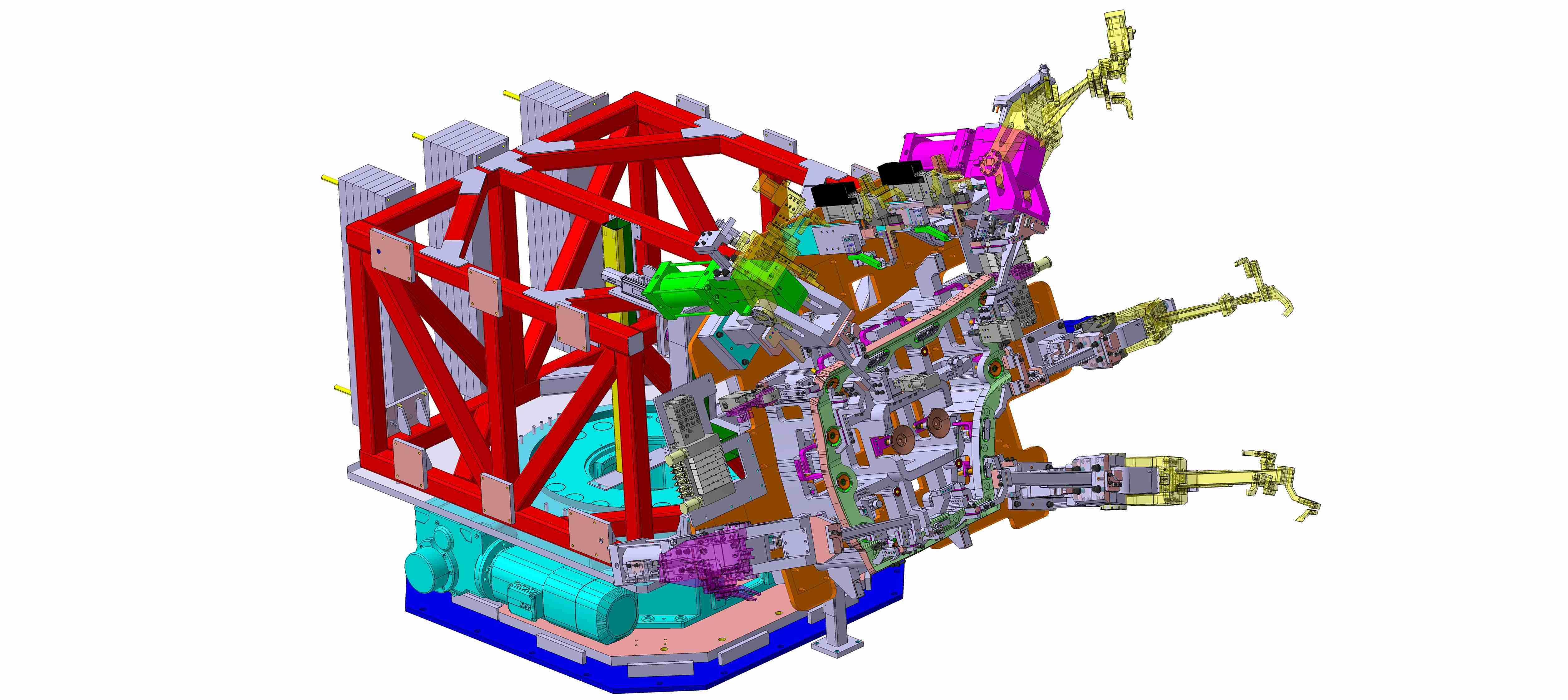

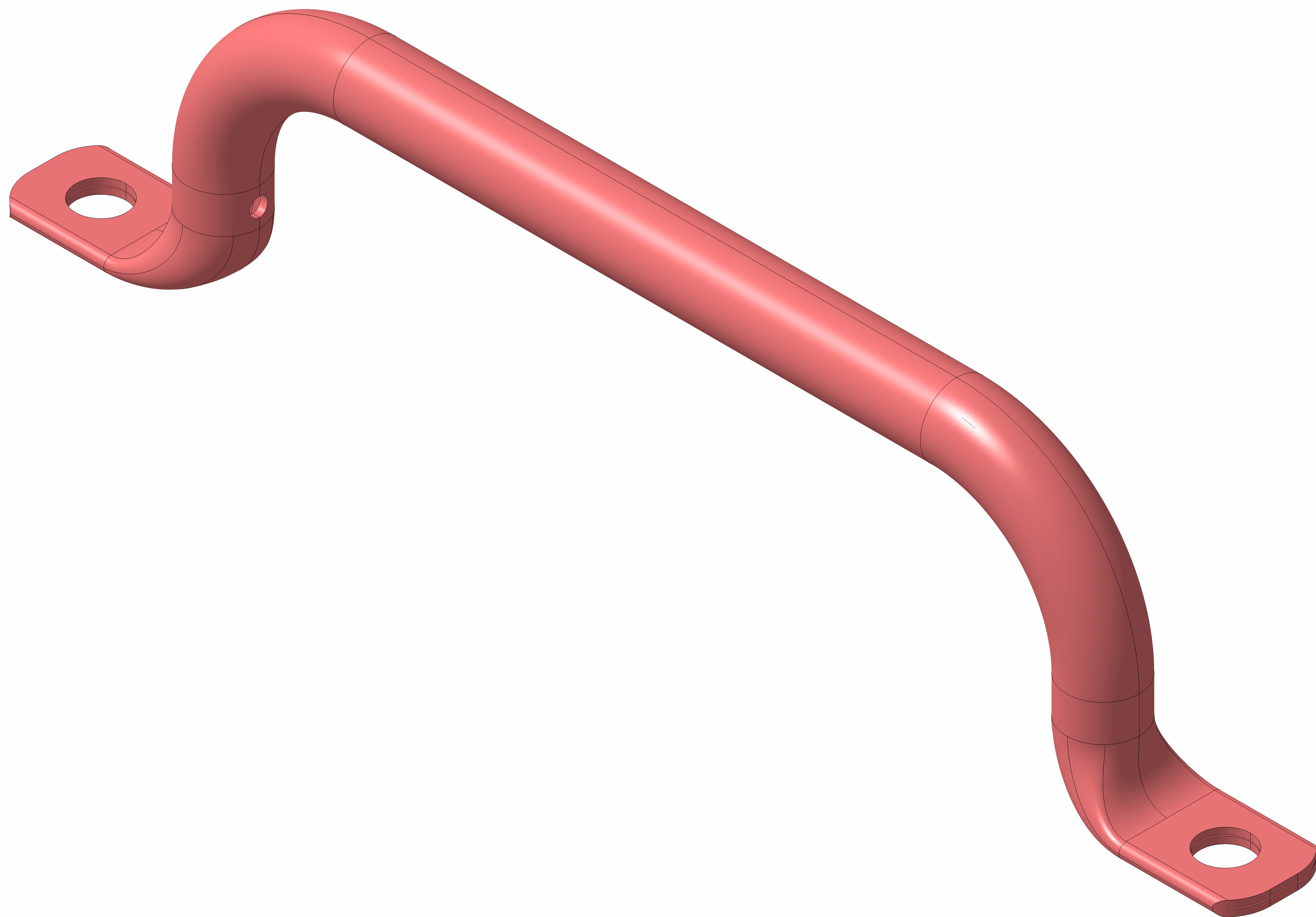

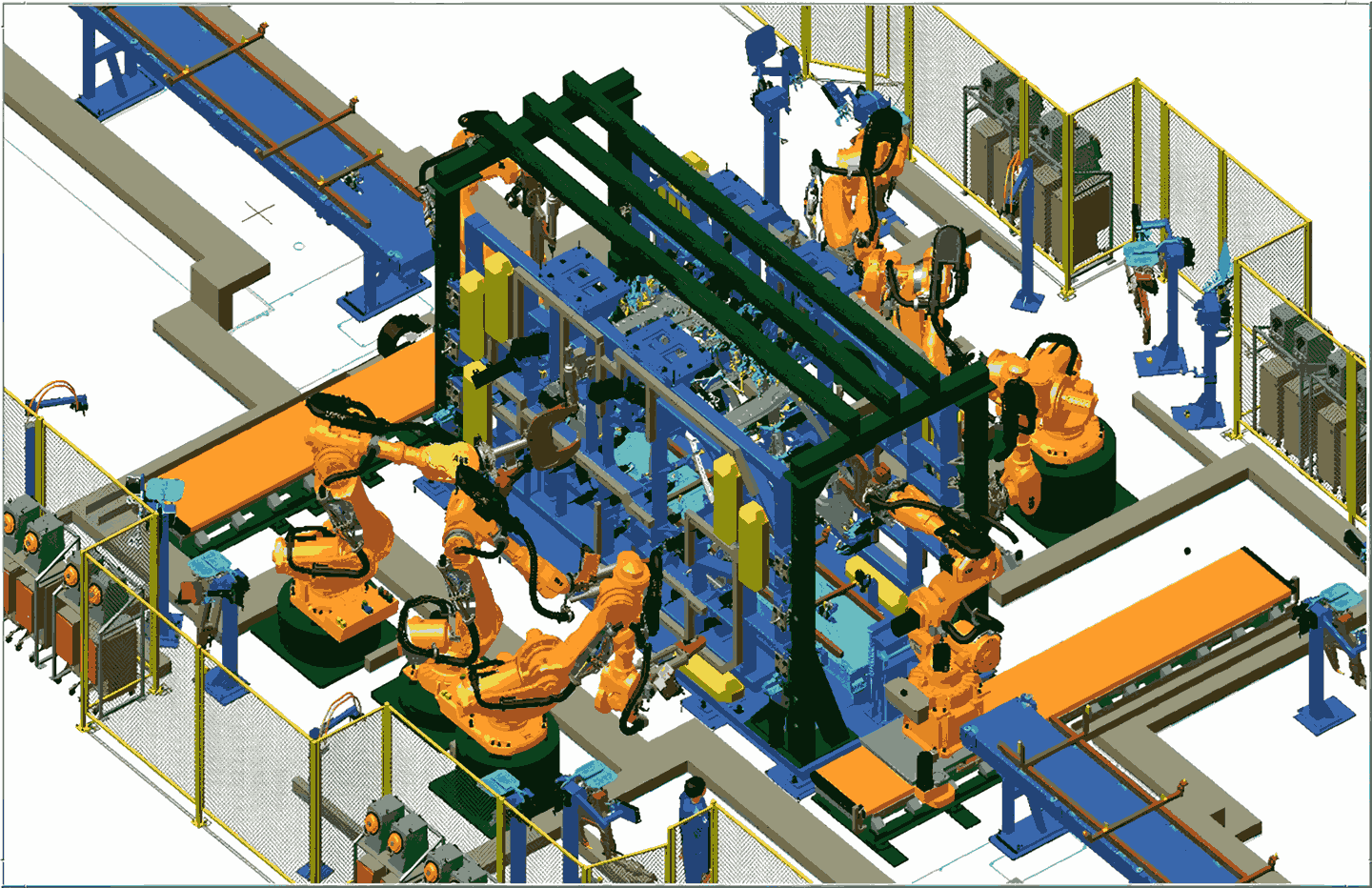

SPM

Special Purpose Machines (SPMs) are custom-built machines designed to handle specific manufacturing tasks that standard machines cannot perform. These machines help automate complex, specialized processes, reducing manual labor and improving precision.

Key Benefits

- Custom-built machines tailored to specific production needs.

- Increased speed and accuracy, reducing defects.

- Cost-effective automation solutions.

We design SPMs to tackle your toughest manufacturing challenges, ensuring each machine meets performance standards before implementation.

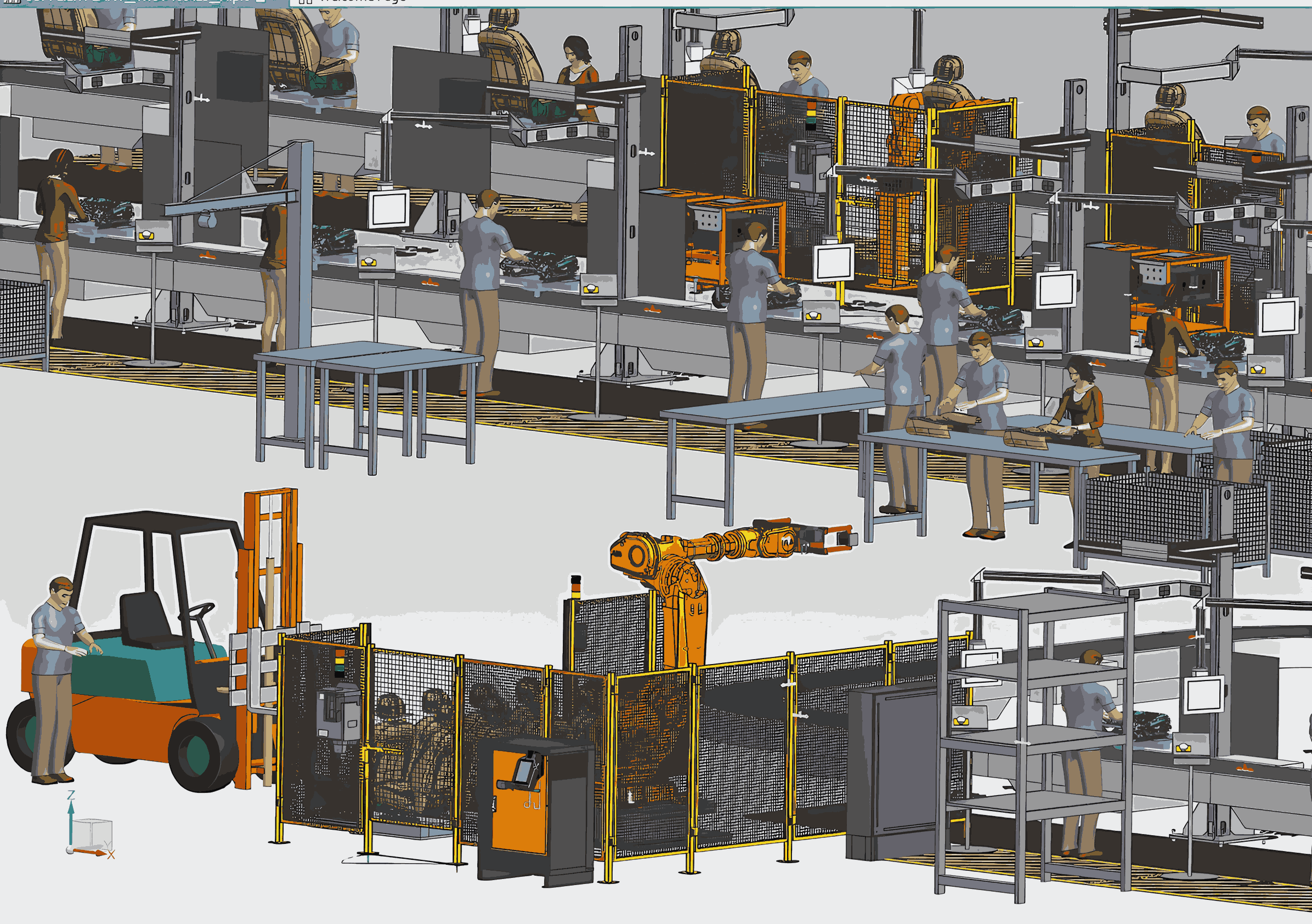

Manufacturing Engineering

Our manufacturing engineering services focus on improving production processes to maximize efficiency and minimize costs. We provide a full spectrum of services that ensure high-quality outputs while optimizing the use of resources.

Core Offerings

- Process planning and optimization for smoother production flows.

- Lean manufacturing techniques to reduce waste and improve productivity.

- Stringent quality control systems to maintain product standards.

We utilize data-driven approaches to enhance manufacturing processes and ensure the best possible output at the lowest cost.

R&D Services

Research and Development are crucial for staying competitive in the manufacturing industry. We offer comprehensive R&D services to help businesses innovate, develop new products, and bring them to market.

Expertise

- Product development and prototyping to bring ideas to life.

- Feasibility analysis and testing to ensure safety and performance.

- Innovative design solutions that enhance product functionality.

We aim to deliver competitive advantages through new technologies, materials, and smarter design approaches.

Full Project Lifecycle Management

We manage the entire lifecycle of your production system, from the initial design phase to installation and ongoing support.

Solutions Offered

- Full Project Lifecycle Management: We manage the entire lifecycle of your production system, from the initial design phase to installation and ongoing support.

- Installation & Operational Support: We provide installation services and operational training, ensuring that your team can run the production system efficiently.

- Process Customization: We offer tailored solutions that meet the specific needs of your production process, optimizing workflows for maximum efficiency.

Our turn-key systems are designed to integrate seamlessly with your existing operations, offering a smooth transition from project inception to full production capability.

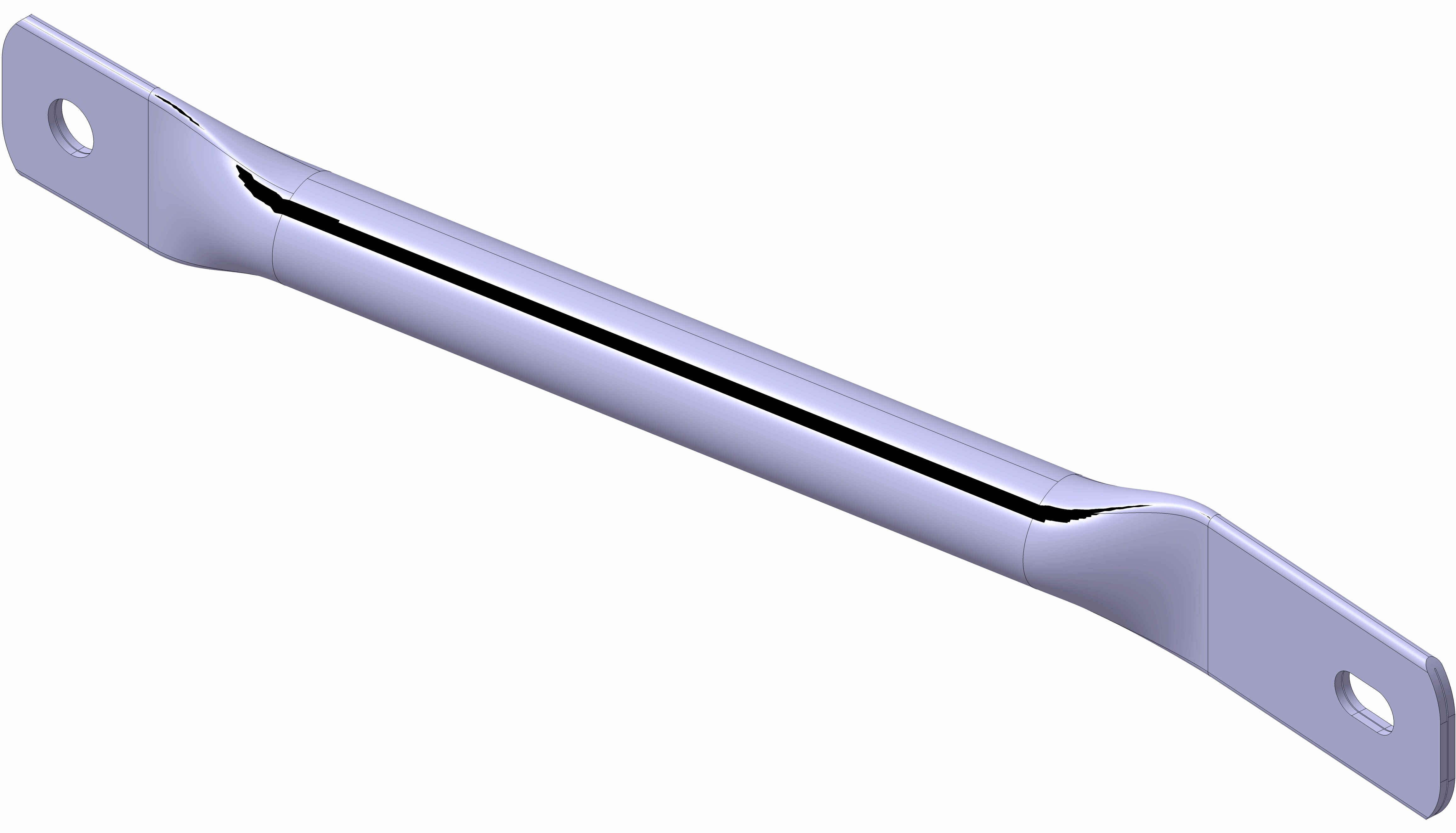

Reverse Engineering

Our reverse engineering services enable businesses to analyze, replicate, and improve existing products. This service is especially useful for parts where original designs are unavailable, outdated, or need enhancement.

Advantages

- Accurate 3D Modeling & Analysis: Using advanced scanning technologies, we create precise 3D models of existing parts to understand their geometry and function.

- Component Enhancement: We offer redesign services to enhance performance, reduce costs, or improve functionality based on reverse-engineered data.

- Legacy Part Reproduction: We help businesses reproduce legacy parts that are no longer in production, ensuring compatibility and performance.

Reverse engineering allows businesses to extend the life of products, reduce downtime, and achieve better designs with advanced manufacturing techniques.

Staffing, Recruiting, Talent Acquisition

Finding the right talent is crucial for the success of any technical project. Our staffing and recruitment services ensure that your team is equipped with the skilled professionals necessary for efficient operations.

Why Choose Us

- Skilled Professionals Across Industries: We offer access to a diverse talent pool, ensuring that you find the right fit for your business needs.

- Streamlined Hiring Process: We handle the recruitment process from start to finish, ensuring a quick and efficient hiring experience.

- Cost-Effective Staffing Solutions: By providing skilled professionals on-demand, we help reduce recruitment costs and time spent on hiring.

Our recruitment services are tailored to technical and engineering positions, ensuring you get the right expertise in areas like manufacturing, automation, and engineering design.